Forget Customers,

We’re Building Partnerships

Any company can have customers‑we prioritize a seamless and responsive end‑to‑end process for lasting partnerships. From the inception of your idea to engineering and mass production, we’ve got you covered.

When you work with our team, you gain access to more than 38 years of design and manufacturing expertise for the development of your custom filters. More importantly, you’re stepping under the protection of the Sun Industries umbrella, where we’re committed to cultivating a relationship with you that lasts a lifetime.

This means we function as a smart and savvy extension of your team, are attentive to the details that most effectively answer your specific needs, and put in the hours and energy to test and validate your filters until we’ve achieved perfect performance and protection.

WHAT WE DO

Research and Development Driven by Relentless Curiosity

Over here, the gears are always turning. From a big picture view down to the most micro-level details, we utilize an immersive approach to research, development, testing, and validation, and that means we leave no stone unturned. With advantages like design prototyping, in-house mold-making, and extensive field testing, our product customization supports the unique needs of our partners worldwide.

Our ProcessWho We Are

Sun Industries Is Always in Your Corner

We pride ourselves on taking a deep dive into the industry challenges our partners face. We’re solution seekers in everything we do, and working with us means you have a team of advocates who are completely aligned to your goals.

Our PrinciplesHOW WE GOT HERE

Over 3 Decades in the Making

We’ve spent the last 38 years forging deep relationships that span every industry. We’ve built our book of business by prioritizing technical innovation, design expertise, manufacturing efficiency, and an extensive testing and validation process. Our decades-long experience and loyalty to our partners means we can help you find and solve problems before you even know they exist.

Our HistoryHOW WE SEE IT

Leaving Our Mark on the Industry

We take pride in setting the standard when it comes to understanding and executing on our partners’ specific needs. Backed by decades of experience, we're working together toward an innovative future of custom-filter manufacturing. We can't wait for you to be a part of it.

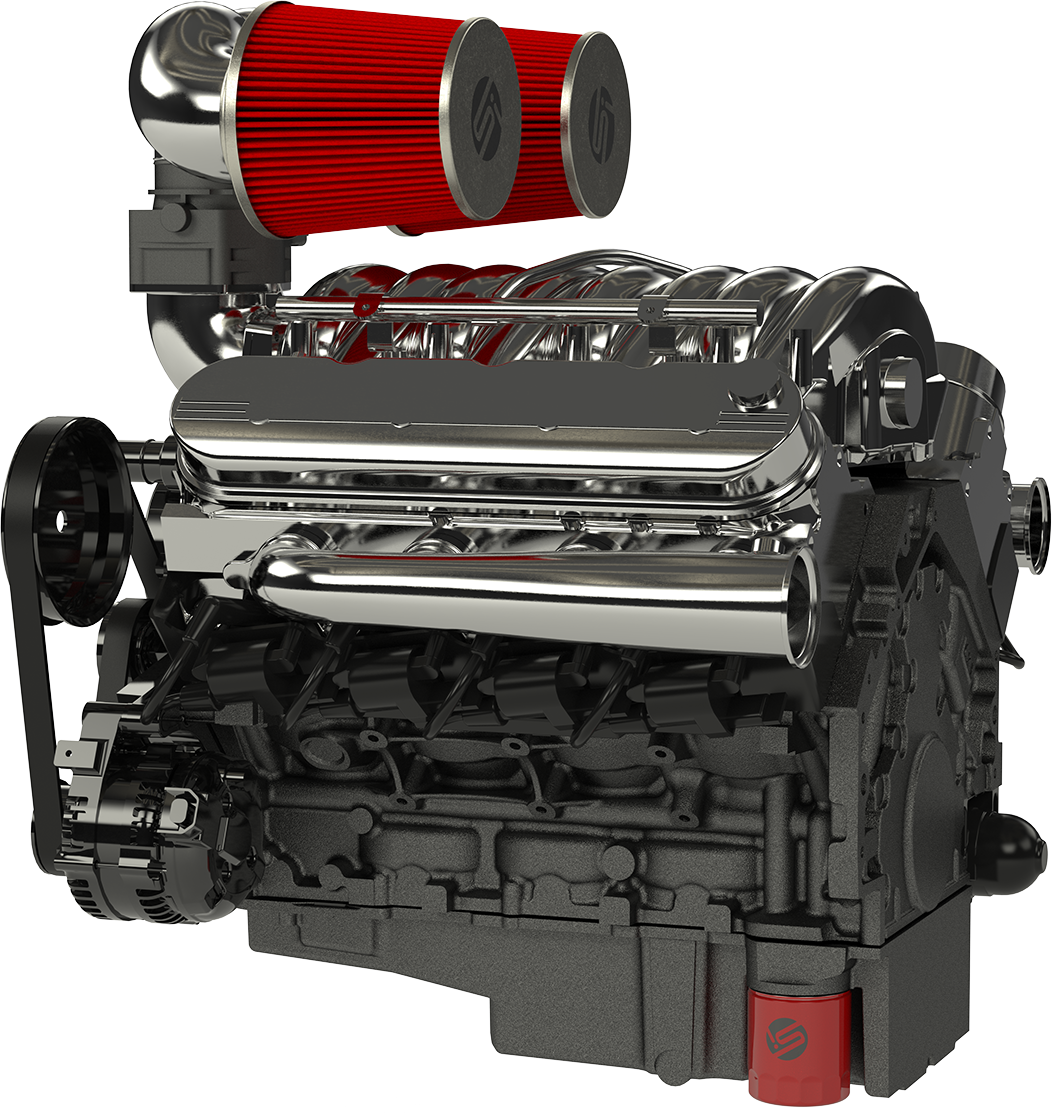

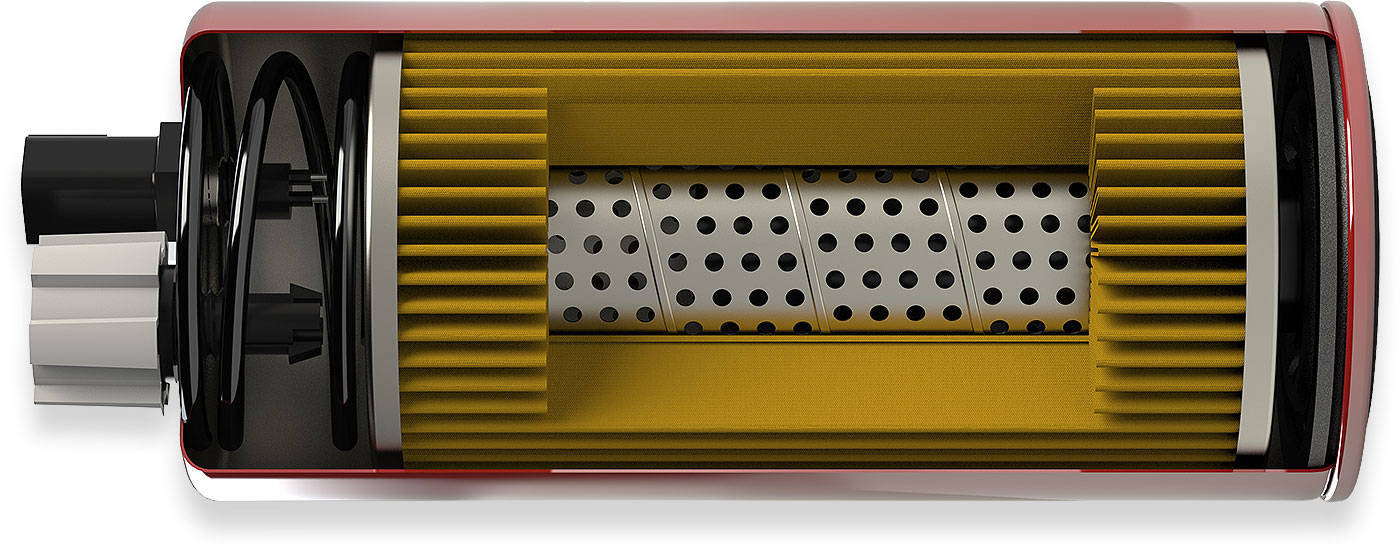

Our VisionWE MANUFACTURE SOLUTIONS

At every step of our end-to-end filter manufacturing process, a core foundation of our company is that we’re always operating in service of your vision. When we partner with you for development, we hold ourselves accountable to the highest standard for precision, accuracy, and performance, from initial concept design to modeling analysis to extensive testing and validation to streamlined mass production.

Parameters and Concept Design

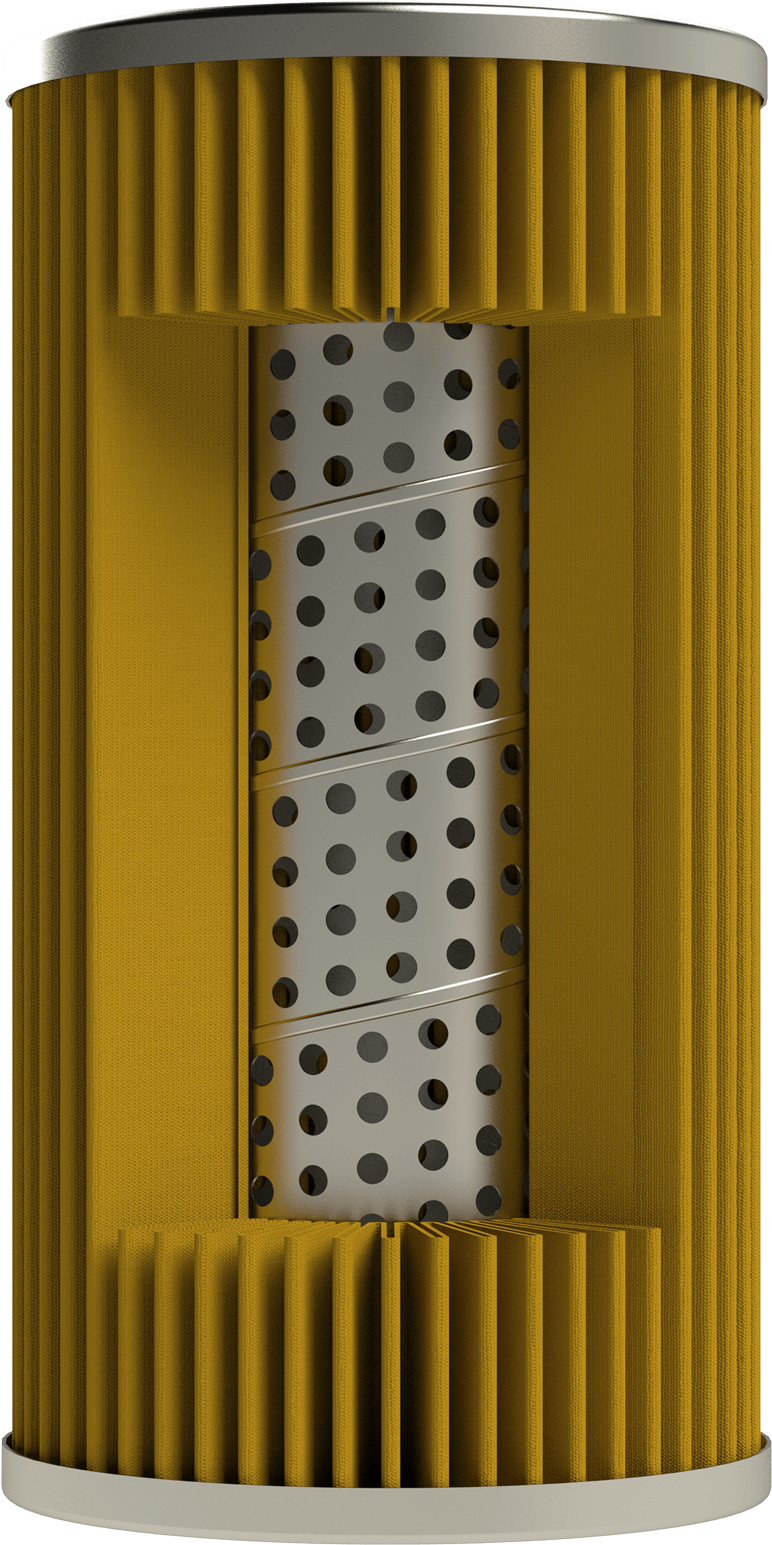

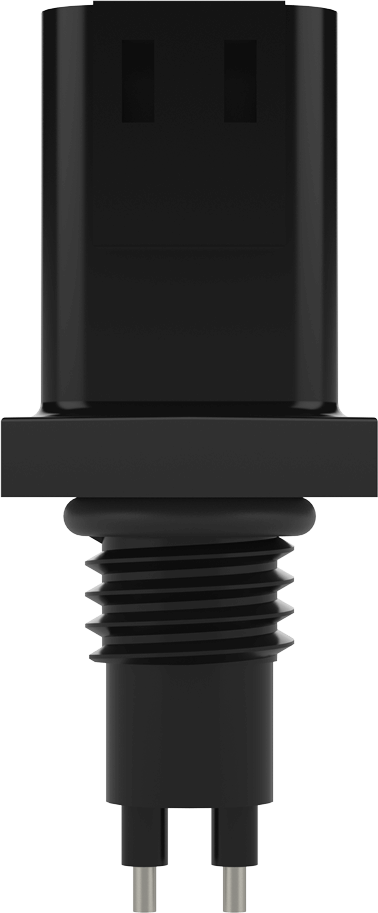

We’ll identify product needs, constraints, and specifications to ensure the custom filter we design meets your exact needs for performance and function. The renderings you see during conceptual design enable us to create each filter to the correct form, fit, and function.

Modeling Analysis

Modeling analysis is our first phase of validation, and it entails simulated testing to answer inquiries about the form and function of your product, as well as how it may operate in a real‑world environment. This phase includes specific product functionality, structural analysis, and thermal analysis.

Prototype

Your prototype creates something tangible from our conceptual designs and modeling analysis findings. Benefits of prototyping include low‑quantity production runs, physical fit tests, and the ability to see, feel, and test the product before mass production.

Testing and Validation

Drawing from our initial modeling analysis, we'll take our prototype to the field. Our products are tested against the highest standards to ensure quality, high performance, and consistency. Our filters are stress‑tested for multiple levels of effective particle removal, temperature levels, and specific real‑world contaminants. We adhere to testing on all required standards: ISO 16889, ISO 19438‑1, ISO 4548‑12, SAE HS 806, SAE J905, ISO 12103‑1, and ISO 16949 to ensure dependable product quality.

Manufacturing

We start with the highest‑grade raw materials, which are then organized and processed in our ISO 9001 & AS9100 certified facility. Our manufacturing capabilities utilize advanced automation and robotics for a streamlined process that assures top‑of‑the‑line quality and efficiency.