We Manufacture Solutions

At every step of our end-to-end filter manufacturing process, a core foundation of our company is that we’re always operating in service of your vision. We’re proud to create specific, custom filter solutions for any challenge our partners face. As your needs evolve, so do our solutions: that’s the Sun Industries way.

Identify Parameters

Every application is unique, which is why our process starts with an in-depth discovery of your end-product vision. In this phase, we’ll identify product needs, constraints, and specifications to ensure the custom filter we design and manufacture meets your exact needs. Whether we’re upgrading an existing filter or building a custom solution from the ground up, this stage enables us to determine every detail necessary to create a filter with the optimal fit, function, compatibility, and performance.

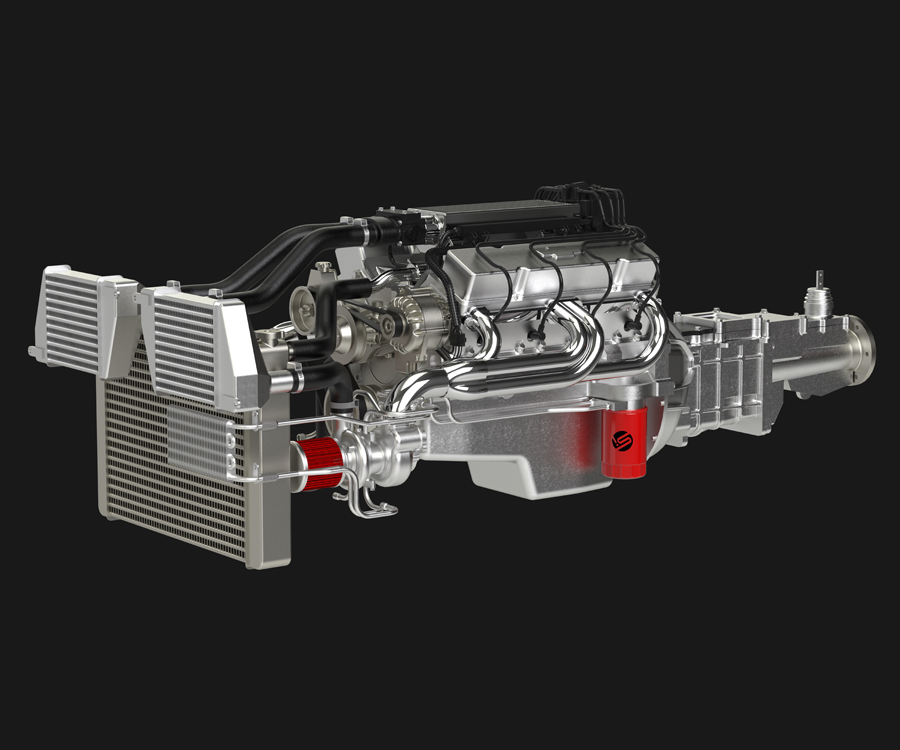

Create a Conceptual Design

Designing your product breathes life into your vision. We’ll begin conceptualizing a design based on the industry and application parameters we’ve identified with you in phase one. Here, we’ll sketch design concepts and use graphical modeling to provide renderings as your product begins to take shape. These concept designs provide a visual sample of the filter in relationship to the end product. Our models can help your engineers visualize an entire system, and they also enable us to design each filter to the correct form, fit, and function.

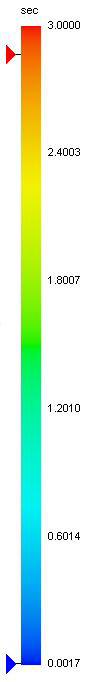

Plastic Fill Time

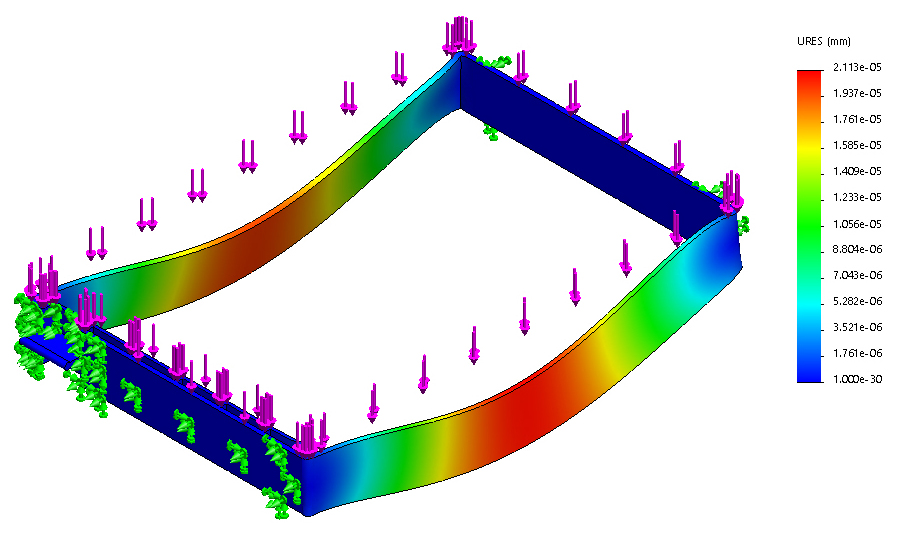

Perform Modeling Analysis

Once the conceptual design is complete, we’ll begin our first phase of validation. Our period of modeling analysis is simulated to answer inquiries about the form and function of your product and how it may operate in a real-world environment. Our analysis includes specific product functionality, structural analysis, and thermal analysis. As we undergo this phase of programmatic testing, we’ll further define parameters and make any necessary changes to your design until we’re satisfied that every mark is being hit exactly the way it’s supposed to be.

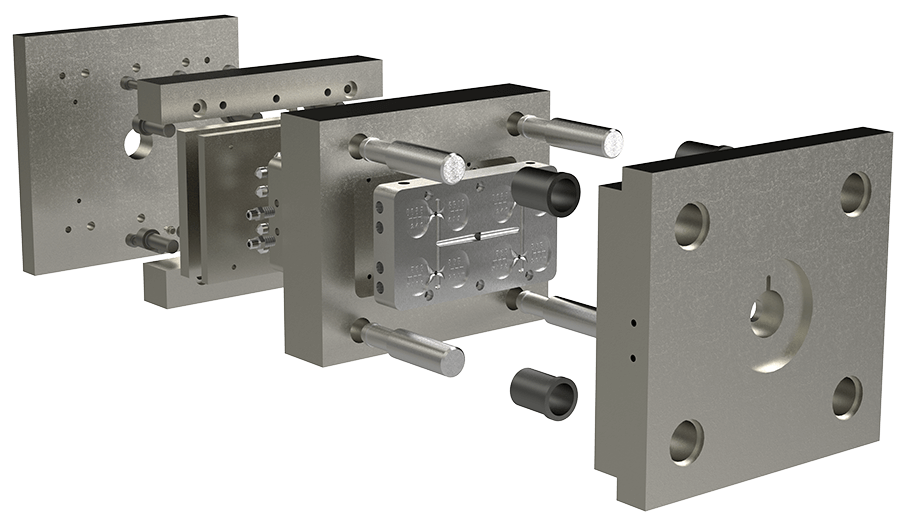

Develop Your Prototype

Development is one of the most exciting parts of the entire process. At this stage, we’re ready to create something tangible from our conceptual designs and modeling analysis findings. This first article prototype will be what we use for our second phase of testing and validation, and it brings us one step closer to manufacturing the bespoke filter you’re looking for. Additional benefits of prototyping include low-quantity production runs, physical fit tests, and the ability to easily address any design modifications along the way. This step also allows our partners to see, feel, and test the product before mass production.

Stringent Testing and Validation

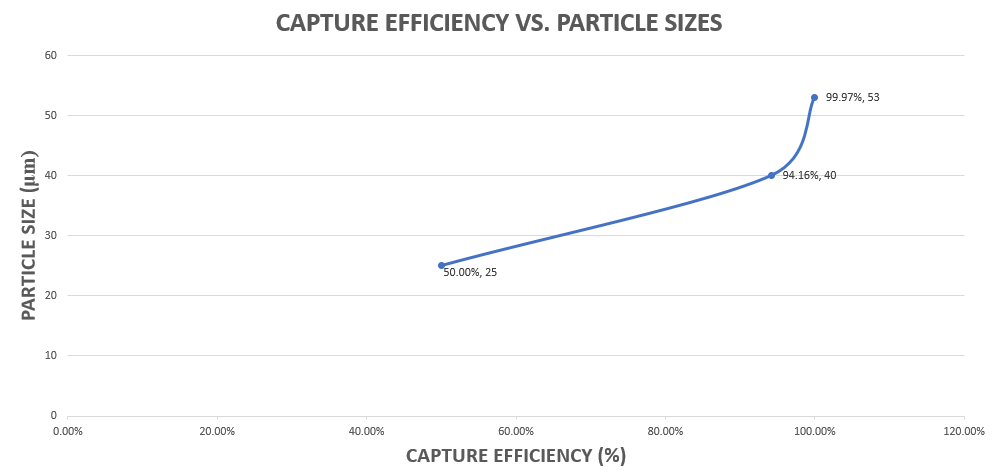

Testing and validation is one of the most critical points in a successful manufacturing process, and it’s a factor that sets us apart in the industry. In this phase, we draw from our initial modeling analysis and take our prototype to the field. Our products are tested against the highest standards to ensure a quality, high-performing, and consistent result. Our filters are stress-tested for multiple levels of effective particle removal, temperature levels, and specific real-world contaminants. In addition, we adhere to testing on all required standards: ISO 16889, ISO 19438-1, ISO 4548-12, SAE HS 806, SAE J905, ISO 12103-1, and ISO 16949 to ensure dependable quality. We perform extensive field testing on every product we create-that’s part of what it means to be your partner in filter manufacturing.

Manufacturing

Once our testing and validation phase has been completed and we have a prototype that meets or exceeds all specifications, it’s time to put your filter out into the world. We start with the highest-grade raw materials, which are then organized and processed in our ISO 9001 & AS9100 certified facility. We understand that the best proof of our commitment to our partners is in the quality of the products we produce. Our manufacturing capabilities utilize advanced automation and robotics for a streamlined process that assures top-of-the-line quality and efficiency across every industry.

Why work with Sun Industries?

Our longevity in the filters industry is a result of our dynamism and commitment to actualizing our partners’ visions. We do this while upholding stringent standards for quality manufacturing. By executing our partners’ needs using our extensive knowledge and expertise, we’re able to ensure the highest levels of performance for every filter we manufacture.

Partner With Us Today