A key element to an effective and efficient valve body screen filter is the mesh used in its design and production, but what does the mesh do exactly? Why is mesh important?

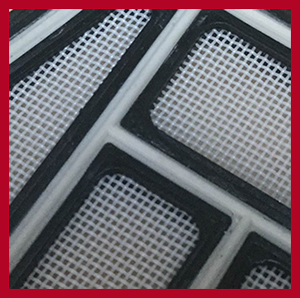

Mesh can be made from a selection of metals or from synthetic fibers. Diverse varieties of mesh can withstand high heat, acute cold, chemicals, solvents and liquids. It can also be manufactured in many sizes and shapes while still maintaining a high strength-to-weight ratio to accommodate all your filtration needs. The requirements of your vehicle and equipment will determine what mesh is best for protecting your transmission.

Mesh can be made from a selection of metals or from synthetic fibers. Diverse varieties of mesh can withstand high heat, acute cold, chemicals, solvents and liquids. It can also be manufactured in many sizes and shapes while still maintaining a high strength-to-weight ratio to accommodate all your filtration needs. The requirements of your vehicle and equipment will determine what mesh is best for protecting your transmission.

Valve body screen filters made with these synthetic mesh materials increase the beneficial qualities such as keeping the transmission fluids clean and ensuring smoother and more efficient gear shifting. Synthetic mesh captures more contaminates in the depth of its layers as opposed to on the surface therefore increasing the filter capacity. The decreased sensitivity of mesh to liquid creates a low resistance that increases flow rates and improves the quality of transmission fluids being filtered. This extends the amount of time between replacements and expands the overall efficiency of your transmission, providing your consumers with a superior product for an economic value.

At Sun Industries, we work with some of the world’s leading aftermarket transmission suppliers and work with a range of mesh materials, from nylon to polyester to steel, to manufacture precision body valve screen filters and plastic panel filters that will improve the transmissions daily and long-term use. Contact us for further information on how our line of body screen and plastic panel filters can support your requirements.